What is Thermostatic Air Vent & How it Improves Steam System Efficiency?

In any steam system, efficiency and reliability are key to maintaining optimal performance and minimizing energy costs. One often overlooked but critical component in achieving this is the thermostatic air vent. Though small and simple in appearance, these devices play a vital role in ensuring steam systems operate at peak efficiency. Let’s explore what thermostatic air vents are and how they help improve steam system efficiency.

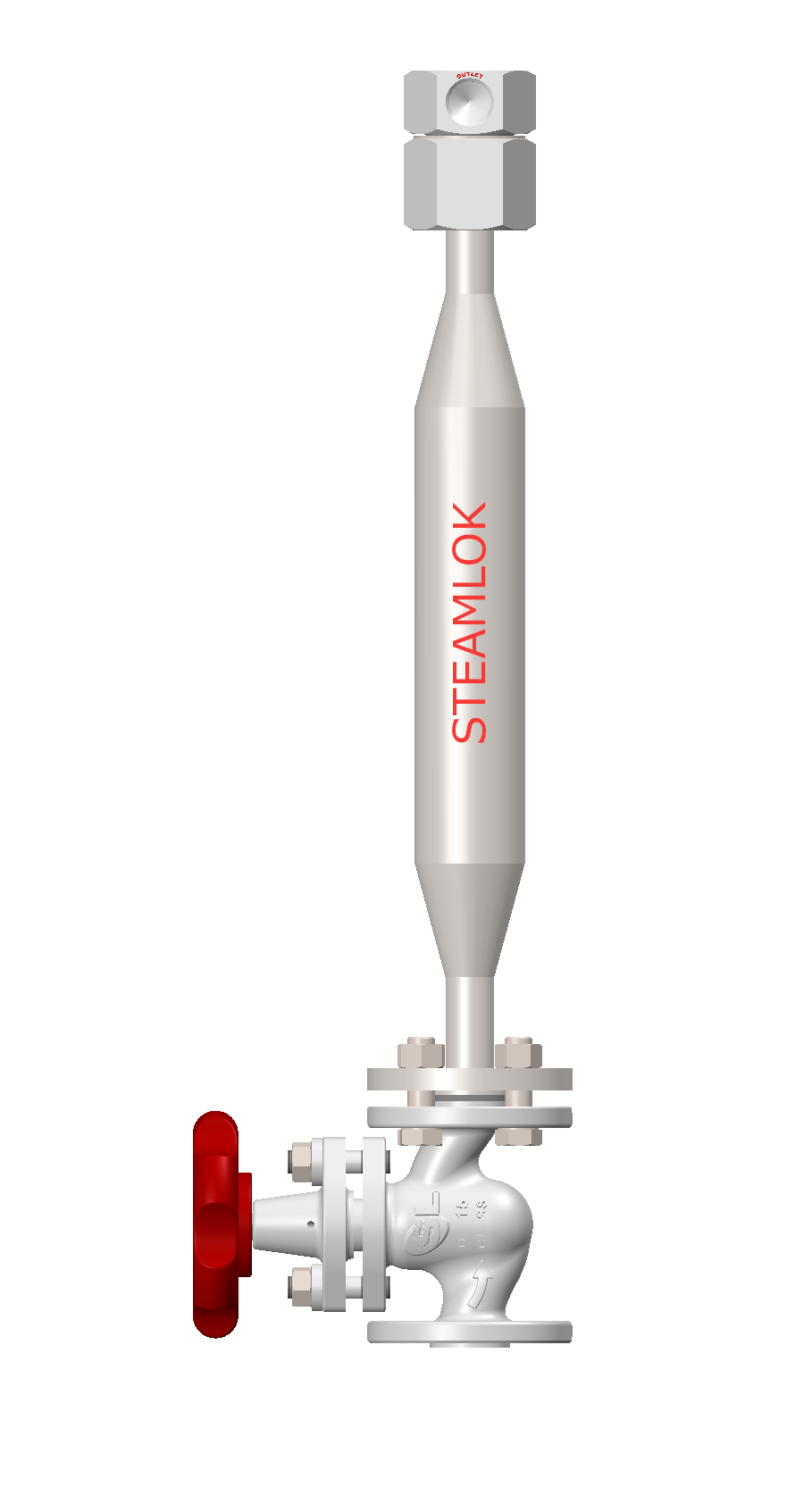

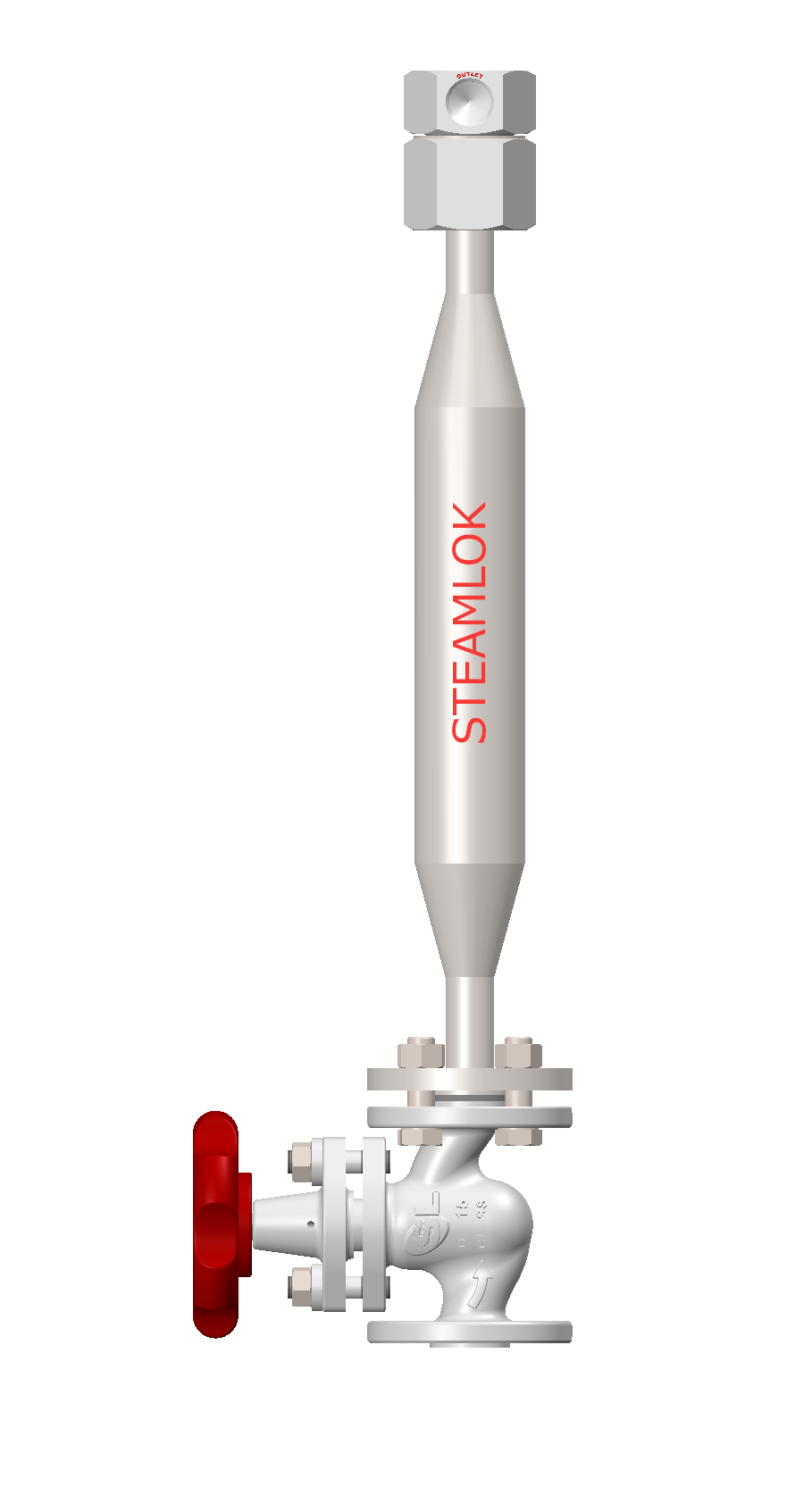

What is a Thermostatic Air Vent?

A thermostatic air vent is a mechanical device used in steam systems to automatically discharge air and non-condensable gases while retaining steam. It operates based on the temperature difference between steam and cooler air/gases.

How It Works:

- When steam is turned on, the system is initially filled with air.

- The thermostatic element (typically a bellows or bimetallic strip) in the air vent remains open at low temperatures, allowing air to escape.

- Once the hot steam reaches the vent, the thermostatic element senses the temperature, expands or closes, and shuts off the vent—retaining steam inside the system.

Why Removing Air is Important

Air and other non-condensable gases present in steam systems act as insulators. Their presence reduces heat transfer efficiency and causes problems like:

- Slow startup of equipment

- Uneven heating

- Corrosion due to oxygen

- Reduced effectiveness of steam traps and other control valves

Removing this air promptly during startup—and continuously where necessary—boosts thermal efficiency and equipment performance.

How Thermostatic Air Vents Improve Steam System Efficiency

- Faster Startup Time

Air must be removed before steam can fill the system. Thermostatic air vents quickly evacuate trapped air, reducing warm-up time.

- Improved Heat Transfer

Air forms a barrier between steam and the heat exchange surface. By removing this air, the vent ensures direct contact of steam, improving the overall heat transfer rate.

- Energy Savings

Efficient removal of air helps prevent steam wastage. If air stays in the system, more steam is required to compensate for the temperature drop. Thermostatic air vents reduce energy loss by maintaining steam purity.

- Minimized Corrosion Risk

Air contains oxygen, a major cause of corrosion in steel pipes and equipment. By venting air, these devices help reduce corrosion and extend the life of system components.

- Reduced Water Hammer

Trapped air can contribute to water hammer by preventing proper condensate drainage. Thermostatic air vents help ensure air-free steam flow, minimizing pressure surges.

Where Are Thermostatic Air Vents Used?

Thermostatic air vents are used in:

- Heat exchangers

- Steam tracing systems

- Jacketed vessels

- Steam mains

- Process equipment requiring fast and efficient heating

Conclusion

While they may seem like a minor part of the steam system, thermostatic air vents are crucial to overall system performance. By ensuring fast air removal, better heat transfer, reduced corrosion, and lower energy usage, they contribute significantly to the efficiency, reliability, and longevity of steam systems.

If you’re designing or maintaining a steam system, don’t overlook the importance of air venting. A small investment in quality thermostatic air vents can lead to substantial savings and improved operational efficiency over time.